Fermenter - Bioreactor touch

Fermenter - Bioreactor touch

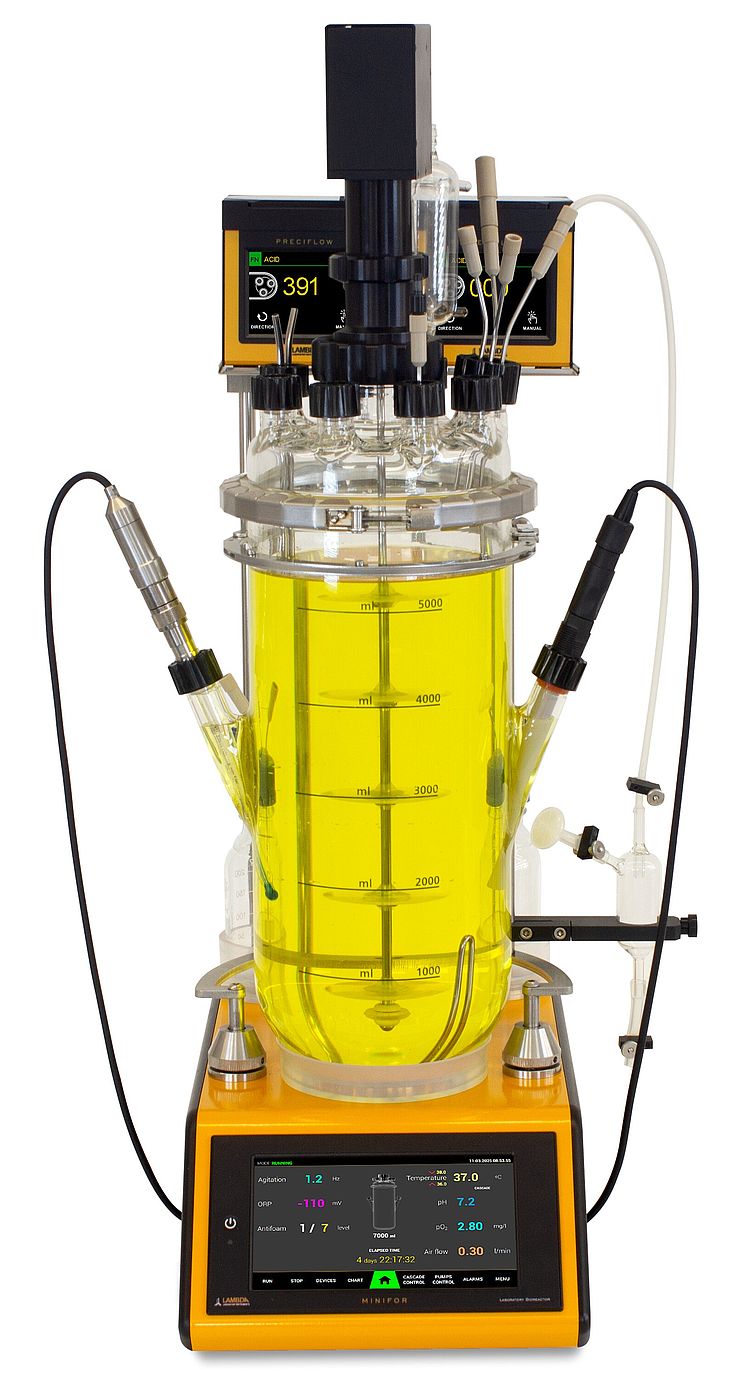

Smart & Ergonomic Benchtop Fermenter-Bioreactor. Equipped with innovative features, this advanced lab-scale fermenter-bioreactor is designed to streamline fermentation and cell culture processes, saving you time and effort.

LAMBDA Minifor2Bio touch Fermenter Bioreactor

The Minifor2Bio touch combines the proven innovations of the LAMBDA Minifor with modern advancements, prioritizing intuitive operation and seamless data management.

It offers real-time monitoring of multiple units, easy integration of additional parameters (ORP, foam detection, optical density, pCO₂, conductivity, etc.), and effortless software updates for enhanced flexibility and performance.

Touchscreen User Interface with an intuitive software package for real-time data monitoring, graph visualization, and data storage. Advanced features like the cascade option provide greater control.

No Heavy Head Plate, No Baffles – Just Smart Design! Say goodbye to bulky, cumbersome components! Our state-of-the-art design ensures seamless handling and user-friendly operation.

LAMBDA Minifor2Bio touch Fermenter Bioreactor: Advanced Bioprocessing in lab scale

Based on long personal practical experience with fermentation and cell culture, we have designed an easy to use system with the capacity to measure and control all the important parameters of the biological culture. With many innovations the Minifor2Bio touch eliminates the common problems of any Bioreactor-Fermenter.

Compact Bioreactor Design with Maximum Accessibility

The LAMBDA Minifor2Bio touch Fermenter-Bioreactor is designed for laboratories seeking efficient bioprocessing. Its compact footprint saves valuable bench space while providing excellent access to ports for seamless sterile operations, ensuring complete sterility.

Interchange the vessels at a very low cost

This bioreactor offers whole glass interchangeable vessels (0.3L, 0.4L, 1L, 3L, and 7L) for fermentation volumes ranging from 35 mL to 6 liters. From microbial culture to cell line development, it supports a wide range of applications in biotechnology and biopharmaceutical research.

Bioreactor with Innovative Non-Rotational Agitation Technology

LAMBDA’s bench-top bioreactor and fermenter features a breakthrough in mixing technology—a novel non-rotational up-and-down agitation system that replaces the traditional propeller-based stirrers. This advanced system eliminates the need for expensive motors and magnetic couplings, reducing costs while enhancing sterility and performance.

Using a cost-effective motor combined with a sterile membrane, the bioreactor achieves powerful and efficient mixing without vortex formation, removing the need for baffles. This vertical agitation is not only highly effective but also gentle on cells and minimizes foam production, making it ideal for sensitive cultures.

Additionally, the integration of biomimicking "fish-tail" stirring discs enhances mixing efficiency. These discs, inspired by nature, work seamlessly with the vertical motion to provide uniform mixing without sharp edges, ensuring both safety and optimal performance.

Intuitive 7” Touchscreen for Enhanced Control

The high-resolution 7” TFT IPS touchscreen (1024×600 pixels) delivers clear visuals from any angle. Its glove-friendly capacitive touch panel ensures smooth and precise control during complex fermentation processes.

Customizable with Comprehensive Bioreactor Accessories

Enhance the system with peripherals like gas analyzers, chemostat-compatible balances, gas flow controllers, anti-foam detectors, and additional feed pumps. This flexibility makes the Minifor2Bio ideal for aerobic and anaerobic bioprocessing.

Accurate Infrared Heating for Optimal Temperature Control

The bioreactor utilizes infrared (IR) heating technology positioned beneath the vessel for even temperature distribution. This gentle heating method mimics natural sunlight, protecting sensitive cultures during cell cultivation.

Integrated Pump Management for Advanced Fermentation

Manage up to five pumps with the built-in software controller. Achieve seamless control for fed-batch fermentation, chemostat operation, and custom feed profiles, ensuring precise nutrient delivery.

Automated pH Control

Maintain the desired pH level with automated base or acid addition through peristatic pumps. The bioreactor’s intelligent pH control ensures stable fermentation conditions for optimized cell growth and product yield.

Smart Cascade Control for Enhanced Bioprocessing

The Minifor2Bio offers advanced cascade control for seamless regulation, for eg: dissolved oxygen (DO) using oxygen enrichment. This is ideal for high-density cell culture.

Efficient Chemostat Mode with Real-Time Weight Monitoring

A built-in balance module monitors culture weight, allowing automated chemostat control for continuous fermentation.

ARC Digital Probe Compatibility for Advanced Analysis

LAMBDA Minifor2Bio supports Hamilton ARC sensors for accurate measurements of pH, DO, ORP, conductivity, CO2, optical cell density, and viable cell density. Digital data ensures enhanced process control.

Integrated Airflow Regulation for Aerobic and Anaerobic Processes

For aerobic fermentation, a gas flow sensor with a proportional needle valve ensures precise DO control. For anaerobic processes, the built-in MASSFLOW controller regulates nitrogen (N2) addition.

Automatic Foam Management for Continuous Operation

The LAMBDA DOZITO miniature syringe pump detects foam formation and adds a minimal amount of anti-foam agent, preventing process interruptions and maintaining efficient fermentation.

Expandable Peripheral Support for Custom Research

With six standard peripheral input ports, the Minifor2Bio supports additional modules to adapt to diverse bioprocessing requirements, ensuring optimal productivity.

Real-Time Data Logging with Timestamping

The bioreactor includes a real-time clock with time zone support, recording and timestamping all process data. This facilitates precise data analysis and compliance with regulatory standards.

Reliable Connectivity for Efficient Data Management

Transfer data via USB or Ethernet (LAN) connections, with an optional Wi-Fi module for wireless monitoring. The connectivity options streamline data management and enable remote process supervision.

High-Performance Dual-Processor System

The bioreactor is powered by a robust dual-processor system featuring a 120 MHz and a 1 GHz Quad-Core CPU. This ensures fast data processing and reliable control for even the most complex bioprocesses.

Ready to elevate your research? Explore the LAMBDA Minifor2Bio touch Fermenter-Bioreactor today and discover how it can transform your work. You can read more at the product page - www.fermenters.eu

NEW! - The new Minifor2Bio touch laboratory fermenters-bioreactors are now available!

Read more: https://fermenters.eu/

Dimensions: 220 x 444 x 350–550 mm (W x D x H)

Display: 7” TFT IPS with resolution 1024x600 and capacitive touch panel

Fermentor vessel: Pyrex borosilicate glass with 6 to 8 threaded necks; 0.3, 0.4, 1, 3, 7 liter vessels

Temperature control: High efficiency 150 W infrared (IR) radiation heat source with gilded parabolic reflector Regulation: From 5°C over RT to 70°C | Measurement: From 0 to 99.9°C in 0.1°C steps | Precision : +/- 0.2°C (0 to 60°C) Sensor: Pt 100 incorporated in the glass electrode of the pH probe

pH control: Sterilizable pH electrode pH 0–14 with automatic temperature correction, two-point calibration and Variopin connector or digital probe ARC. Range: 0 to 14.0 pH unit | Resolution: 0.1 or 0.01 pH unit (adjustable) - Analog probe types: Analog autoclavable Hamilton/Mettler Toledo pH-probe with Pt 100 temperature sensor or similar with Variopin connector -Digital probe types: Hamilton ARC technology with Variopin 8 connector

pO2 control: Sterilizable Clark-type oxygen sensor with fast response, automatic temperature correction, two-point calibration, dissolved oxygen (DO) control through regulation of the airflow rate or cascade controller. Range: 0 to 25 mg oxygen/ l, in 0.1 mg/l steps, 0–100% saturation (adjustable units) | - Resolution: 0.1 or 0.01 (adjustable) -Analog probe type: LAMBDA sterilizable Clark type oxygen sensor with fast response -Digital probe type : Hamilton ARC technology (Clark type or optical)

Air flow: 0 to 5 l/min in 0.01 l/min steps, measured by precise mass flow meter, linearity +/- 3%, reproducibility +/- 0.5% Control: Proportional valve controlled by microprocessor Supplied air pressure: 0.05 – 0.2 MPa (0.5 - 2 atm)

Agitation: 50 W Vibromixer 0 to 20 Hz (0 to 1200 rpm) in 0.1 Hz steps (6 rpm) with 1 or more stirring discs; Sterility similar to magnetic coupling

Type: Active peripherals (DEVICES): Device managed by internal software manager - Pumps: PRECIFLOW touch, HIFLOW touch, MAXIFLOW touch, MEGAFLOW touch - Gas flow regulators: MASSFLOW 500 touch, MASSFLOW 5000 touch - Exit gas Analyzers: OXYMETER touch, CARBOMETER touch, METHANMETER touch - Balance: BALANCE 20

Ports / side necks: One large quadruple sampling or additions port with four needles with LAMBDA PEEK double-seal connections, used for sampling, inoculation, antifoam, feeds, harvest, addition of correction solutions etc., additional double ports are available

Gas flow control: Configurable gas mixing: Several electronic flow controllers with flow rate ranges of 0-5 l/min (MASSFLOW 5000) or 0-500 ml/min (MASSFLOW 500) can be used for the controlled addition of gases (e.g. N2, O2, air, CO2) in cell cultures.

Interface: USB 1.1/2.0 type B (PC control) | USB 1.1/2.0 type A (Host) for data export or software updates | LAN | WIFI (optional)

PC control: Software application MIRETO for online monitoring, manage and data download

Working temperature: 0 - 40 °C

Working humidity: 0 - 90 % RH, not condensing

Weight: 7 Kg

- EN:LAMBDA Minifor2Bio touch Laboratory Fermentor-Bioreactor_leaflet (pdf)

- __DE: LAMBDA Minifor2Bio touch Labor Tisch Fermenter-Bioreaktor_Broschüre (pdf)

- __FR: LAMBDA Minifor2Bio touch fermenteur-bioréacteur de paillasse_brochure (pdf)

- __ES: LAMBDA Minifor2Bio touch fermentador-biorreactor de sobremesa_folleto (pdf)

- **EN: LAMBDA Minifor2Bio touch Fermenter-Bioreactor Operational manual (pdf)

- EN: Mireto Control Software for Minifor2Bio touch Fermenters-Bioreactors- Leaflet (pdf)

- __DE: Mireto - Steuersoftware für LAMBDA Minifor2Bio touch Fermenter-Bioreaktoren_Broschüre (pdf)

- __FR: Mireto_Logiciel de contrôle pour fermenteurs-bioréacteurs LAMBDA Minifor2Bio touch_brochure (pdf)

- __ES: Mireto_Software de control para fermentadores-biorreactores LAMBDA Minifor2Bio touch_folleto (pdf)

- EN: LAMBDA touch Peristaltic Pumps Leaflet (pdf)

- __DE: LAMBDA touch_Schlauchpumpen_Broschüre (pdf)

- __FR: LAMBDA touch_pompes péristaltiques_brochure (pdf)

- __ES: LAMBDA touch_Bombas Peristálticas_folleto (pdf)

- **EN: LAMBDA touch Peristaltic Pumps Operational Manual (pdf)

- EN: LAMBDA touch Massflow Gas Flow Regulators Leaflet (pdf)

- __DE: MASSFLOW touch Gasfluss messen & regeln - Broschüre (pdf)

- __ES: LAMBDA MASSFLOW touch - caudalímetro de gas - folleto (pdf)

- __FR - Régulateur de débit de gaz LAMBDA MASSFLOW touch- brochure (pdf)

- **EN: LAMBDA touch Massflow Gas Flow Regulators Operational Manual (pdf)

Short selected scientific Publications Using LAMBDA Minifor Fermenter-Bioreactor

Recombinant Protein Expression & Genetic Engineering

- Cas9 protein expression in E. coli – Ménoret et al.

DOI: 10.1038/ncomms8577 - Ribosomal protein quantification in yeast and mESCs – Slavov et al.

DOI: 10.7554/eLife.03023 - Chemokine expression in E. coli – Kramp

DOI: 10.1007/s10529-014-1474-9 - Chemokine expression for cardiovascular research – Projahn

DOI: 10.1161/ATVBAHA.113.302461 - Caf1 protein expression for adhesion studies – Machado Roque

DOI: 10.1186/1471-2091-14-23

Mammalian Cell Culture

- Hybridoma growth and mAb production in MINIFOR – Howard & Kaser

DOI: 10.1201/9781420005196 - González M, Aragón H, Medel M, Hernández D, Ferro W, Llamo A, et al. Continuous culture of mouse hybridoma cells for 100 Days in the Lambda MINIFOR bioreactor. Biotecnol Apl. 2024;41(2):2211-8. The mouse hybridoma producing the CB.Hep-1 monoclonal antibody (mAb) was cultivated for 100 days in protein-free medium using a Lambda MINIFOR bioreactor

- pH & temperature monitoring with SIAM software – Chaignon et al.

Fermentation & Biofuel Production

- Lactose-to-ethanol fermentation – Pasotti et al.

DOI: 10.1016/j.ijbiomac.2015.03.038 - Date extract fermentation with S. cerevisiae – Putra et al.

DOI: 10.1080/10826068.2013.811649 - Biobutanol from agricultural waste – Mezule et al.

DOI: 10.2478/v10161-012-0028-5 - Bioethanol production using MINIFOR – Burešová & Hřivna

DOI: 10.1016/j.apenergy.2010.10.036 - Glucose fermentation from date extract – Gaily et al.

DOI: 10.2202/1556-3758.1879 - Bioethanol from tree tobacco stems – Sánchez et al.

ResearchGate - Bioethanol from prickly pear – Sánchez et al.

ResearchGate

Biofilm Studies & Oral Microbiology

- LAMBDA MINIFOR as artificial mouth system – DENTAID

Website - Six-species flow cell model using MINIFOR – Salli & Ouwehand

DOI: 10.3402/jom.v7.26149 - Growth of oral bacteria (planktonic) – Blanc et al.

DOI: 10.1111/jre.12110 - Continuous flow biofilm model with MINIFOR – Soto

DOI: 10.1111/jre.12110

Microbial Growth & Metabolic Studies

- Yeast glycolysis and energy flux – Slavov et al.

DOI: 10.7554/eLife.03645 - Tomato cell response to low oxygen – Ampofo-Asiama et al.

DOI: 10.1016/j.plantsci.2014.08.011 - S. marcescens growth in MINIFOR – Mohammed

DOI: 10.1186/s12934-014-0125-4 - S. aureus under benzalkonium chloride – Cervinkova et al.

DOI: 10.1111/jam.12269 - Anaerobic expression using MINIFOR – Park et al.

DOI: 10.1128/jb.00828-07

Algae & Plant Cell Culture Studies

- Chlorella vulgaris for CO₂ capture – Heitur

DOI: 10.1016/j.algal.2014.03.002 - Tomato cell culture under low oxygen – Ampofo-Asiama et al.

DOI: 10.1016/j.plantsci.2014.08.011

Bioreactor Technology & Instrumentation

- Photobioreactor design paper

DOI: 10.1562/2005-08-03-RA-637 - Innovations in MINIFOR bioreactor technology – Lehky

PDF

What are the main differences between the MINIFOR and the Minifor2Bio Touch?

- The primary difference is the user interface. The Minifor2Bio Touch features several upgrades compared to the MINIFOR, including LAN connectivity for remote fermentation management using the Mireto software, onboard data storage, and convenient data acquisition via USB or PC.

- Additional advantages of the Minifor2Bio Touch include integrated Redox measurement, allowing the pH probe to be easily swapped with a combined Redox-pH probe at a low cost, and built-in antifoam detection — removing the need for external instruments.

- Moreover, accessories like the MASSFLOW regulators and pumps now come with touchscreen interfaces for seamless operation, aligning with the Minifor2Bio Touch's modern design.

- If you plan to add advanced probes like pCO2 or turbidity sensors in the future, the Minifor2Bio Touch offers a more cost-effective solution. Unlike the MINIFOR, which requires both a probe and an external transmitter (e.g., from Hamilton or Mettler), the Minifor2Bio Touch eliminates the need for a separate transmitter.

How to transfer the stored data to PC?

- The recorded values pH, pO2, temperature, Optical density, ORP etc...can be transferred to a PC or laptop through a USB. The stored data can be used further in Excel, word or txt files.