Microbial Cultivation in corrosive Environments in the LAMBDA MINIFOR Fermenter-Bioreactor

The innovative design of the LAMBDA MINIFOR Fermenter-Bioreactor makes it more suitable for specialized applications where corrosive media, such as seawater, are used in cell cultivation.

MINIFOR Bioreactor Design: Minimizing Stainless Steel Exposure to the Culture

Traditional fermenters often rely heavily on stainless steel components, which are prone to corrosion when exposed to seawater or other saline solutions. The LAMBDA MINIFOR bioreactor overcomes this limitation by offering Teflon cannulas as an alternative to stainless steel. This design minimizes direct metal exposure to the culture medium, significantly reducing the risk of corrosion and ensuring long-term reliability.

Seawater, with its high salinity and oxidative properties, can rapidly degrade even high standard SS 316 bioreactor materials. However, the MINIFOR bioreactor’s very minimal SS exposure makes preferable choice for applications like marine research and hydrocarbon biodegradation studies.

Fig1: The MINIFOR Fermenter-Bioreactor with the Teflon cannulas and Silicone agitation disc

Key Features of the LAMBDA MINIFOR Bioreactor

- High-Quality Glass Vessel: The primary culture vessel is crafted from durable, chemically resistant glass, providing both strength and a clear view of the fermentation process.

- Corrosion-Resistant Teflon Cannulas: Unlike traditional stainless steel (SS 316) components, the optional Teflon cannulas are non-reactive and ideal for aggressive media like seawater. This prevents contamination and maintains the purity of the culture.

- Biomimicking Fishtail Agitation Without Baffles: Instead of conventional blades, the MINIFOR bioreactor uses silicone discs that move up and down for mixing. The stainless steel impeller can also be wrapped in Silicone or Teflon to prevent direct contact with the culture medium, ensuring rust-less operation without compromising functionality. Similarly, 3 small worm screws used to fix the agitating silicone disc can also be sealed with a sealant to avoid direct contact to the media.

In a recent study on the biodegradation of petroleum hydrocarbons in seawater using Pseudomonas sp. Bacteria the LAMBDA MINIFOR Bioreactor-Fermenter is used.

Biodegradation of Petroleum Hydrocarbons in Seawater using the LAMBDA MINIFOR Fermenter-Bioreactor

The LAMBDA MINIFOR bioreactor has proven its effectiveness in real-world applications, as demonstrated in a recent study by the research students from the National University of Trujillo, Peru on the biodegradation of petroleum hydrocarbons in seawater using Pseudomonas sp. bacteria. The study focused on evaluating the biodegradation efficiency of Diesel-B5 under controlled laboratory conditions. The bioreactor was loaded with 500 mL of sterilized seawater artificially contaminated with Diesel-B5 at concentrations of 10%, 15%, and 20%. A microbial inoculum (0.5%-1.0% of the medium volume) of Pseudomonas sp. was introduced at concentrations ranging from 1.0 × 10⁵ to 1.0 × 10⁶ CFU/mL to initiate biodegradation.

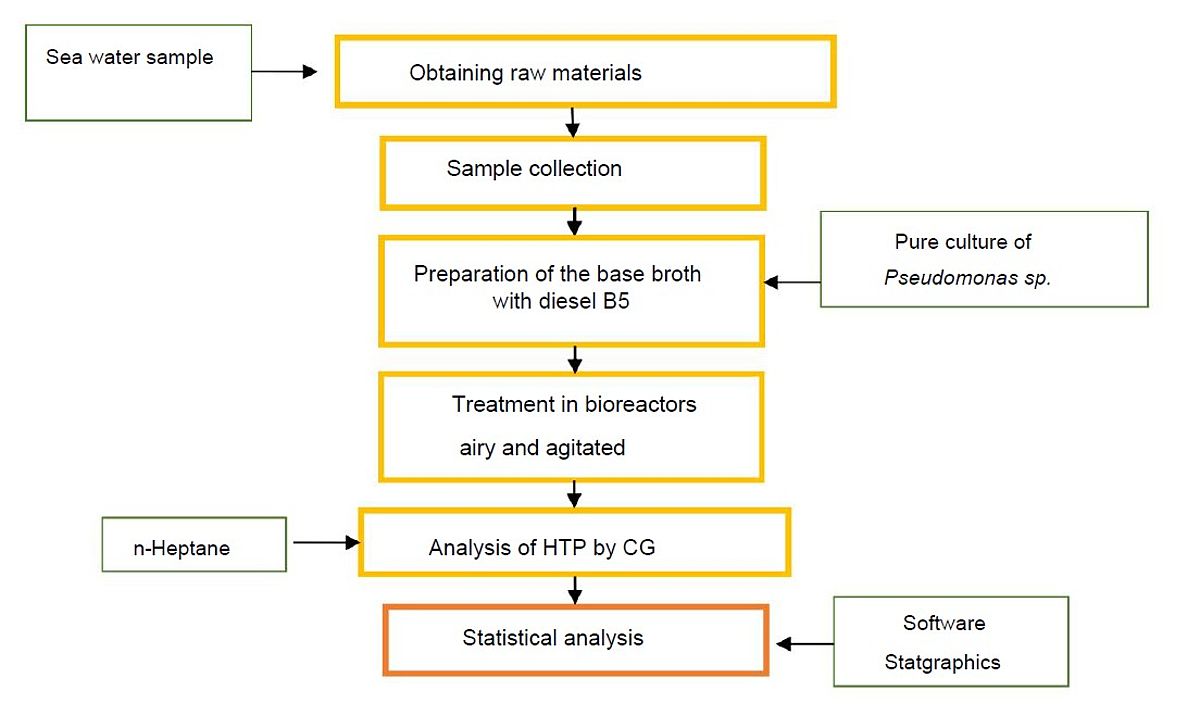

The process involved preparing a base medium with Diesel-B5, adding the inoculum, and monitoring biodegradation progress using gas chromatography (GC) to analyze the remaining total petroleum hydrocarbons (TPH). The study employed a bifactorial experimental design to assess the effects of varying Diesel-B5 concentrations (10%, 15%, and 20%) and temperature levels (25 °C, 35 °C, and 45 °C).

Results showed that the highest biodegradation rate occurred at 35 °C with a 20% Diesel-B5 concentration, achieving a remarkable biodegradation efficiency of 70.9%.

Fig 2: Schematic work overview. Reference: Determinación del ratio de biodegradación de hidrocarburos totales de petróleo empleando Pseudomonas sp. en agua de mar contaminada con diésel-B5. Universidad Nacional de Trujillo, Unidad de Postgrado en Ingeniería Química, Tesis de maestro en ingeniería química ambiental - https://hdl.handle.net/20.500.14414/22166

Why to choose the LAMBDA MINIFOR Fermenter-Bioreactor?

The LAMBDA MINIFOR Fermenter-Bioreactor stands out with simple solution for researchers working with corrosive media like seawater. Whether you are studying marine ecosystems, developing bioremediation strategies, or conducting specialized cell cultivation, the LAMBDA MINIFOR bioreactor offers unmatched reliability and efficiency. Its ability to handle corrosive media like seawater while maintaining culture integrity ensures that your research achieves the highest standards of accuracy and reproducibility.

Ready to elevate your research? Explore the LAMBDA MINIFOR Fermenter-Bioreactor today and discover how it can transform your work with corrosive media. Contact us at sales@lambda-instruments.com for more information and quotation. You can find more information at www.lambda-instruments.com